Accelerators Inc., was one of the

first companies to develop a commercially available ion

implanter for production of semiconductor implantation.

In 1970

they shipped their first accelerator, the IMPLANTER

l, to Hughes in Newport Beach, CA.

1972,

released a 200-Kev system, the IMPLANTER ll.

1973, the

first production system with a carousel end station, the

MODEL 200MP.

1974, the first MOS

system dedicated to low energy implants was released,

MODEL TA80.

1975, released the first

3" wafer, automated cassette-to-cassette system, MODEL

200WE.

1976, released the first

4" (100mm) automated wafer handling system, MODEL

200WE-100.

1977, released the most

popular system ever developed. The first time cryopumps were

used for the vacuum system to produce a contamination free

vacuum. Simple operation, low maintenance, maximum uptime and

a small footprint modular design soon became the industry

standard. The MODEL AIM 210.

Factory Location: 212 Industrial

Blvd., Circle S Dr., Austin TX

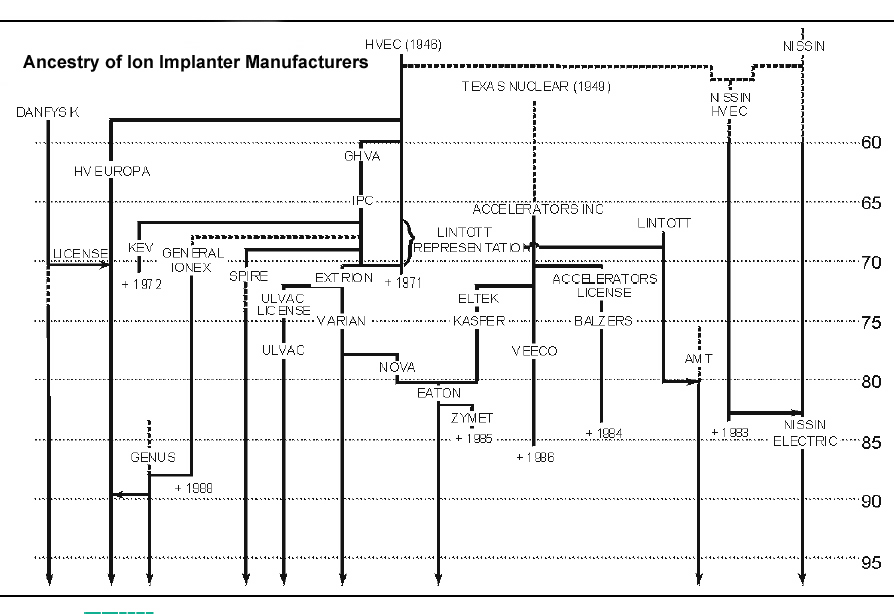

Besides

Accelerators Inc., other companies involved with

laboratory-type accelerators were:

Bell Laboratories,

1950's

AFCRL, 1960's

Ion Physics/Signetics,

1960's

High Voltage

Engineering, 1969

Hughes, 20% shareholder

of Accelerators Inc. stock

Extrion Corp., began

production equipment in 1971. A start-up company formed by

employees of High Voltage Engineering.

7401 Circle S Road, Austin, TX (Now

Artcarved)

212 Industrial Blvd.,

Austin, TX (Now Austin Tool & Baker Distributing

Co.)

1611

Headway Circle #1A, Austin, TX (Now the home of

Accelerated Technologies)

|